MENUProduct center

BacktrackYour location:Home → Product's → IMD gas high pressure forming machine

Description

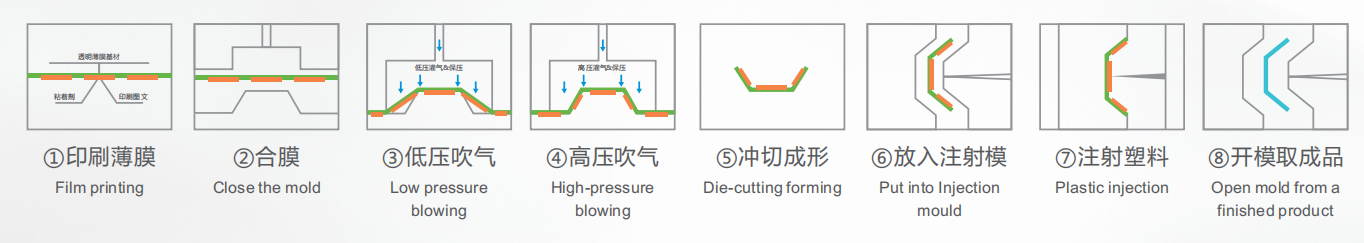

IMD (In-Mold Decoration,or Film Insert Molding) technology uses Decorated (Screen Printed),3-D Formed, and Trimmed film material as the thin shell,then plastic is inserted into the back side of this thin shell by injection molding process to make the decorated components.

By this special process, it is very easy to make plastic components with complex curve, 3-dimentional shape with registered symbols, multi-colored decorations,as well as the light-transmitting design.IMD process can take over many post-molding operations like heat-transter printing, screen printing,spray painting,laser-etching or electro-plating on the plastic injected components thus to save a lot of production cost.

It also gives unlimited decoration possibilities with precisely registered graphics on the plastic components.Back-side printing

decoration application makes IMD products scratch and chemical resistant to achieve the long lasting finishes.

Ultra-high pressure film forming technology is a new generation of forming technology, which has the following advantages:

1. Very low residual stress of the formed film.

2. Only one pair of forming mold core (lower mold) is needed, and there will be no problem of film surface scratches caused by direct contact of the mold on the film surface.

3. Excellent pattern sealing and forming accuracy.

4. Fast production process speed.

5. It is very easy to replace and calibrate the mold.

6. Low mold production cost.

Features:

1. Mechanism design: The whole machine adopts aluminum alloy frame and paint shutter, with high-grade appearance and easy cleaning. With the function of entering and exiting the mold, the operation is convenient and labor-saving;

2. Safety design: equipped with safety electric eye, automatic sound and light alarm function to ensure safety;

3. Model calibration function: with fast and slow calibration mode selection function, so that the mold calibration is more acc